From simple tooth sharpening to extensive tool repair, our service technicians employ a seven point process to restore your worn, dull or damaged tools to their original working condition.

From simple tooth sharpening to extensive tool repair, our service technicians employ a seven point process to restore your worn, dull or damaged tools to their original working condition.

-

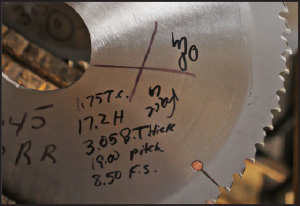

1) Inspection:

1) Inspection:

Tools undergo ultrasonic cleaning, and a thorough inspection to determine needed repairs.

2) Tip Replacement:

NAP Gladu uses only the highest quality carbide and silver solder. Damaged tips are replaced with new ones and ground to exact specifications.

3) Straightening:

Utilizing close tolerance testing, even the slightest misalignments on saw blades are identified and corrected.

4) Hammering/Retensioning:

A process rarely offered by other companies, our certified Hammer-smiths, restore proper tension to the saw body, extending saw life & improving cut quality. -

5) Sharpening:

Our proprietary, high precision process grinds each tooth on the face, top and sides, to produce .

6) Cleaning/Polishing:

For better cuts and less drag, all cutting tools are completely cleaned and polished to put the finishing touch on our comprehensive program.

7) Final Inspection:

All saw blades are inspected and measured to ensure they meet our exacting tolerance for runout, and cutting edges are verified with a 200x microscope inspection.

Find Your Service Center

With 12 service centers across the U.S.

Contact your local rep

and Canada, service is a phone call away.